As technology evolves, it has become increasingly important for companies and industries to stay up-to-date on the latest advancements. SMD connectors play a crucial role in many industrial applications, so it’s essential to know their use and functions. This comprehensive guide will explain everything you need to know about SMD connectors and how they can help your business succeed!

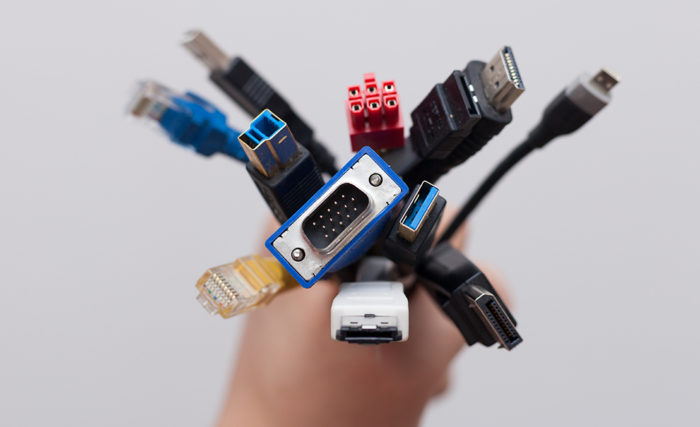

SMD connectors are a type of electrical connector used in a variety of industrial applications. These connectors are designed to be used with printed circuit boards (PCBs) and surface-mount devices (SMDs). SMD connectors are available in a wide range of sizes, shapes, and styles to accommodate the specific needs of your application.

When selecting an SMD connector for your application, it is important to consider the number of pins, pitch, and style of the connector. The number of pins will determine the number of conductors that can be connected, while the pitch refers to the spacing between the pins. The style of the connector will evaluate how the connector mates with the PCB or SMD.

To ensure a reliable connection, selecting an SMD connector with a compatible mating system is important. A mating system consists of two parts: a plug and a receptacle. The plug connects to the PCB or SMD, and the receptacle connects to the power or control device. The receptacle can be either soldered or screwed onto the device.

There are many benefits to using SMD connectors in industrial applications. These connectors offer a high degree of reliability and durability and a low profile that minimizes installation space requirements. In addition, SMD connectors are typically easier to install than other electrical connectors.

Types of SMD Connectors

There are numerous SMD connectors on the market, each with its own set of characteristics and advantages. Though not all SMD connectors are made equal, choosing the appropriate one for your specific application is crucial. The most popular SMD connector types are listed below:

DIP (Dual In-Line Package) Connectors: These are the most common type of SMD connectors used in electronic applications. DIP connectors consist of two rows of pins that connect to an electronic circuit board.

SIP (Single In-Line Package) Connectors: These SMD connectors are similar to DIP but only have one row of pins. SIP connectors are used in high-density applications where space is limited.

PGA (Pin Grid Array) Connectors: PGA connectors have a grid of pins that connect to an electronic circuit board. They’re often used in applications requiring high pin counts or bandwidths.

BGA (Ball Grid Array) Connectors: BGA connectors consist of a grid of balls that connect to an electronic circuit board. They’re commonly used in flat panel displays and other high-density applications.

LGA (Land Grid Array) Connectors: LGA connectors have a grid of land contacts that connect to an electronic circuit board. LGA offers superior electrical performance and is used in high-speed applications.

QFP (Quad Flat Package) Connectors: These SMD connectors have a grid of pins that connect to an electronic circuit board. They’re commonly used in microcontrollers and other integrated circuits.

Applications of SMD Connectors in Industrial Machines

The true beauty of SMD connectors is their versatility. They can be used in various industrial applications, from medical equipment to large-scale manufacturing machines. Here are just a few examples of how SMD connectors can be used in industrial applications:

Medical Devices: SMD connectors are used in medical devices such as scanners and X-ray machines. They provide a reliable connection between the device and its power source.

Manufacturing Equipment: SMD connectors are also commonly used in manufacturing equipment, such as assembly line robots and conveyor belts. Their small size makes them perfect for connecting components in tight spaces.

Telecommunications Equipment: SMD connectors are often used in telecommunications equipment, such as cell towers and base stations. They provide a reliable connection between the equipment and the network.

Automotive applications: SMD connectors are also used in automotive applications, such as engine control modules and navigation systems. Their small size and reliability make them perfect for connecting automotive components.

Tips for Choosing the Right Connector

When it comes to choosing the correct connector for your industrial application, there are a few things you need to take into account. Here are some tips to help you choose the suitable SMD connector:

- Know Your Application Requirements

The first step is to understand the requirements of your application. What type of environment will the connector be used in? What kind of signal will be transmitted? What are the power requirements? Answering these questions will help you narrow down your options and choose the suitable SMD connector for your application.

- Consider The Size And Location Of The Connector

The size and location of the connector are important factors to consider when choosing an SMD connector. Make sure that the connector you choose is small enough to fit in the available space and that it can be accessed easily.

- Choose A Connector With The Right Number Of Pins

Another essential factor to consider is the number of pins on the connector. You need to ensure that the connector you choose has enough pins to accommodate the signals you need to transmit. If you need more clarification, it’s always better to err on caution and choose a connector with more pins than you need rather than one with too few pins.

- Consider The Cost Of The Connector

The cost of a connector is another factor to consider when making your decision. Make sure you compare the price of different connectors and find one that meets your needs without breaking the bank.

- Consider The Connector’s Durability

Finally, make sure the connector you choose is durable enough to withstand any harsh conditions it may encounter in its application. Check the types of materials the connector is made of and how much stress it can bear. This will ensure that your SMD connector lasts as long as possible.

These tips help you choose a suitable connector for your application. Always consider your application’s requirements and ensure the selected connector meets them.

Common Issues with SMD Connectors and Troubleshooting Solutions

Surface mount device (SMD) connectors are prone to various issues, including poor connection. Due to their small size and the fact that they are often located in hard-to-reach places, SMD connectors can be challenging to troubleshoot. However, some common issues can occur with these connectors, and some solutions can help you get your SMD connector working correctly again.

One of the most common problems with SMD connectors is a poor connection. A number of factors, including loose connections, corroded contacts, or damaged terminals, can cause this. If you suspect your SMD connector is not making a good connection, try tightening the connection or cleaning the contacts with a mild abrasive. If this does not solve the problem, you may need to replace the connector.

Another common issue with SMD connectors is contamination. This can happen if the area around the connector needs to be cleaned or if there is moisture. To clean a contaminated SMD connector:

- Use a cotton swab soaked in isopropyl alcohol.

- Gently scrub the area around the pins and terminals until all the dirt and grime have been removed.

- Once the area is clean, dry it off entirely before reconnecting the connector.

If your SMD connector isn’t working after trying these troubleshooting tips, it’s time to call a professional. With their experience and knowledge, they’ll be able to quickly identify the problem and help you get your SMD connector working again.

Summary of Key Points

- SMD connectors are an essential part of industrial applications.

- They are available in various sizes and shapes to meet the demands of different industrial applications.

- SMD connectors offer a high level of reliability and durability compared to other types of connectors.

- They can be used in various temperatures and environments.

- SMD connectors are easy to install and require minimal maintenance.